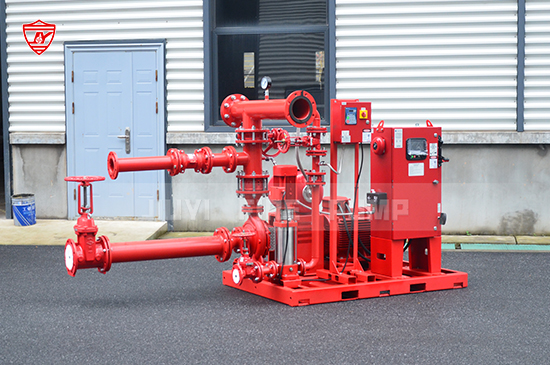

Fire pumps are critical components in fire suppression systems, providing the necessary water pressure to combat fires. However, the performance of fire pumps can be significantly impacted by altitude, which affects their efficiency and reliability. In areas of high elevation, where atmospheric pressure is lower, the pump's ability to move water may diminish, leading to reduced flow rates and pressure. This is particularly important when designing fire protection systems for buildings, industrial plants, or remote facilities located at higher altitudes.

At sea level, fire pumps are designed to work optimally, with standard atmospheric pressure and density allowing for maximum pump output. As altitude increases, the air pressure and oxygen levels decrease, affecting both the engine performance and the pump's efficiency.

Lower Atmospheric Pressure

As altitude rises, the air pressure decreases, which means there is less air to drive the pump. This can cause a reduction in the volume of water that the pump can supply, as the pump is less effective at moving water without the necessary pressure. In some cases, fire pumps may struggle to achieve the required flow rate and pressure needed for fire suppression.

Reduced Engine Power

Fire pumps powered by internal combustion engines—whether electric, diesel, or hybrid—may face a decrease in engine performance at higher elevations. Engines rely on oxygen in the air for combustion. With less oxygen available at higher altitudes, the engine's output can decrease, leading to lower pump performance. For diesel engine pumps, this is especially critical, as reduced oxygen levels affect combustion efficiency.

NPSH (Net Positive Suction Head) Issues

NPSH is a key factor in pump performance, especially for centrifugal pumps. At higher altitudes, the reduction in atmospheric pressure can lower the NPSH, leading to cavitation or vaporization of water within the pump. Cavitation causes damage to the pump impellers and reduces its efficiency.

To mitigate the impact of altitude on fire pump performance, manufacturers and engineers take several steps to ensure reliable operation.

Choosing the Right Pump Design

Selecting fire pumps specifically designed for higher altitudes is essential. These pumps are built to handle the lower atmospheric pressure and reduce performance loss. They may include larger impellers or modified internal components to ensure adequate flow and pressure.

Engine Adjustments

For diesel engine pumps, choosing an engine that is either turbocharged or has an increased air intake system can compensate for the reduced oxygen levels at higher altitudes. This adjustment helps maintain engine power and pump output.

Regular Testing and Calibration

Fire pumps installed at high altitudes should be regularly tested to ensure they are still meeting the required performance standards. Adjusting calibration settings based on altitude-specific conditions can help maintain optimal efficiency.

Consideration of Redundancies

In high-altitude locations, redundancy in the fire protection system can ensure reliable operation during emergencies. This includes backup pumps or systems to handle unforeseen issues with altitude-induced performance degradation.

Altitude plays a significant role in fire pump performance, impacting both the engine and the pump's ability to deliver sufficient flow and pressure. For areas located at higher elevations, it's crucial to use fire pumps that are designed for such conditions, ensuring that they provide reliable and effective fire suppression. By understanding these altitude-related challenges, building engineers and safety managers can take the necessary steps to ensure fire pump systems are up to the task in high-elevation environments.