When a fire emergency arises, the reliability of fire pumps can mean the difference between disaster and safety. Regular testing ensures these critical systems function as intended during high-pressure situations. Here’s an in-depth look at the best practices for testing fire pumps in emergency scenarios to ensure optimal performance and compliance with safety standards.

Testing fire pumps is not just a safety measure—it’s also a regulatory requirement. Standards such as NFPA 20 and NFPA 25 outline the necessary procedures for inspection, testing, and maintenance of fire pump systems. Following these guidelines ensures compliance and helps maintain operational integrity.

Weekly churn tests, also known as no-flow tests, involve running the fire pump without discharging water into the system. This allows you to:

Annual flow tests are critical to assess the pump’s capacity under simulated emergency conditions. During this test:

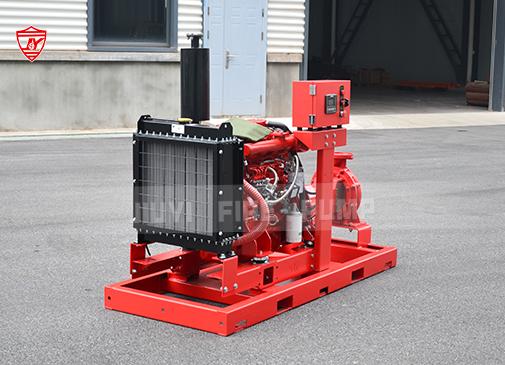

Diesel engine fire pumps require additional attention due to their reliance on fuel and mechanical components. Key steps include:

During any fire pump test, ensure that alarms, controllers, and auxiliary equipment like pressure relief valves are functioning correctly. This ensures the entire system operates seamlessly during an emergency.

Documenting all fire pump tests is essential for compliance and troubleshooting. Include details like:

While some basic checks can be performed in-house, professional technicians with expertise in fire pump systems should conduct comprehensive tests. Certified professionals ensure compliance with standards and provide expert insights.

Regular testing of fire pumps is not just about compliance—it’s about saving lives. By adhering to best practices, monitoring system performance, and addressing issues proactively, you can ensure that your fire pumps are ready when they’re needed most. Partner with a reliable manufacturer like Better Pump to guarantee the quality and reliability of your fire pump systems.