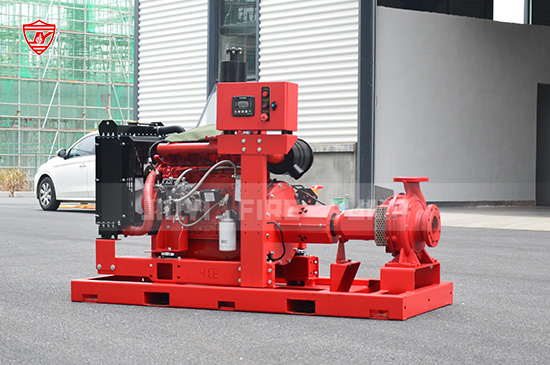

A diesel engine fire pump system is a critical component of fire safety infrastructure, providing reliable water flow in emergencies when electric power may be unavailable. To ensure optimal performance, understanding its key components is essential. Here’s an overview:

The pump is the heart of the system, converting mechanical energy into hydraulic energy to provide water flow and pressure. Commonly used types include horizontal split-case, vertical turbine, and end suction pumps.

The diesel engine drives the pump, offering an independent power source to ensure functionality during power outages. It must comply with industry standards like NFPA20.

The controller manages the system’s operation, ensuring the engine and pump activate as needed. Advanced controllers often feature monitoring systems for real-time diagnostics.

A robust fuel system is vital for uninterrupted operation. It includes a fuel tank, piping, filters, and gauges to maintain consistent engine performance.

These systems regulate engine temperature and expel combustion gases safely. Proper maintenance of these components is crucial for system longevity.

Batteries power the starter motor for the diesel engine. A well-maintained battery system ensures rapid engine ignition during an emergency.

The system’s piping and valves deliver water to the pump and manage flow direction. High-quality materials and proper installation prevent leaks and inefficiencies.

Each component plays a unique role in ensuring the system operates effectively under high-stress conditions. Regular maintenance and adherence to industry standards ensure reliability and compliance.