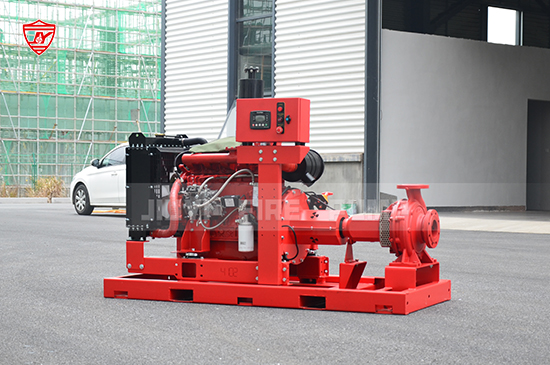

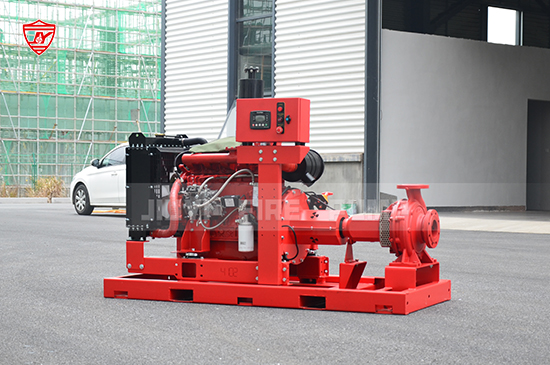

A diesel fire pump is a crucial component of a fire protection system, ensuring reliable water supply during emergencies. Proper priming is essential to prevent dry running, maintain efficiency, and comply with NFPA 20 standards. This article provides a step-by-step guide on how to correctly prime a diesel fire pump to ensure its optimal performance.

Why Priming is Important

Priming removes air from the pump and suction line, allowing water to flow properly. Failure to prime the pump can lead to cavitation, overheating, and potential damage to the system.

Step-by-Step Guide to Priming a Diesel Fire Pump

-

Check the Water Source

- Ensure the water supply is open and unobstructed.

- Verify that the suction line is submerged to prevent air intake.

-

Inspect the Pump and Suction Line

- Check for leaks, air pockets, or damaged gaskets.

- Ensure all valves are in the correct position for priming.

-

Fill the Pump Casing with Water

- Open the priming valve or remove the priming plug.

- Slowly pour water into the pump casing until it is full.

-

Use a Priming Pump (If Available)

- Some systems have a manual or automatic priming pump to remove air.

- Run the priming pump until a steady flow of water is observed.

-

Start the Diesel Engine

- Engage the pump and monitor the pressure gauge.

- If pressure remains low, repeat the priming process.

-

Monitor the System

- Once primed, ensure there are no air leaks.

- Regularly check pressure and suction levels to maintain efficiency.

Final Tips for Diesel Fire Pump Priming

- Regularly inspect the priming system for blockages or leaks.

- Train personnel on proper priming procedures to ensure quick response in emergencies.

- Follow manufacturer guidelines and NFPA 20 standards for compliance.