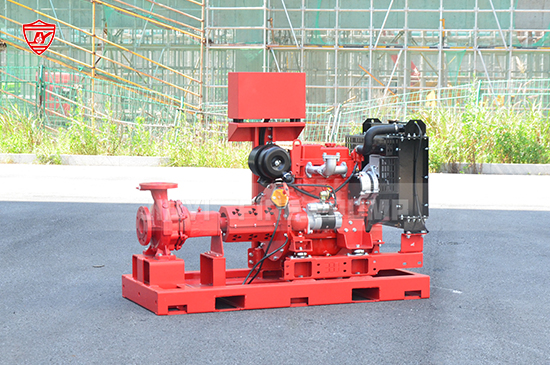

Proper alignment between a diesel engine and a fire pump is critical for ensuring reliable performance, reducing mechanical wear, and preventing costly failures. Misalignment can lead to excessive vibration, shaft damage, and premature component failure. This guide covers the essential steps for achieving precise alignment and maintaining your fire pump system in top condition.

A well-aligned diesel engine and fire pump:

Before installing the fire pump and diesel engine, verify that the foundation is level and rigid. Uneven surfaces can cause alignment issues from the start.

To achieve precise alignment, use tools like:

Properly align the flexible coupling to prevent unnecessary stress on the shafts. The manufacturer’s specifications should be followed precisely to ensure correct spacing and angular alignment.

After securing all components, perform a final check:

Routine maintenance and inspections are essential for keeping the alignment intact. Factors like temperature fluctuations, foundation settling, and normal wear can cause misalignment over time. Periodic checks with alignment tools help ensure continued reliability.

Proper alignment of a diesel engine to a fire pump is essential for maximizing efficiency, reducing wear, and ensuring dependable fire protection. By following these steps, you can extend the lifespan of your fire pump system and avoid costly repairs.