Diesel fire pumps play a critical role in fire protection systems, providing reliable water pressure during emergencies. However, overheating is a common issue that can lead to pump failure, reduced efficiency, and costly repairs. Understanding the causes and implementing preventive measures can help ensure optimal performance and long-term reliability.

Inadequate Cooling System

Diesel engines require efficient cooling to dissipate heat. A malfunctioning or clogged radiator, insufficient coolant levels, or a failing water pump can lead to overheating.

Blocked or Dirty Heat Exchanger

A heat exchanger transfers excess heat from the engine to the cooling system. Dirt, debris, and mineral buildup can reduce its efficiency, causing excessive heat retention.

Insufficient Airflow

Poor ventilation around the pump room or restricted airflow to the radiator can trap heat, preventing proper cooling.

Overloading and Prolonged Operation

Running a diesel fire pump beyond its rated capacity or for extended periods can generate excessive heat, leading to potential damage.

Faulty Thermostat or Sensors

A defective thermostat may fail to regulate coolant flow, while inaccurate temperature sensors can prevent proper cooling adjustments.

Regular Cooling System Maintenance

Optimize Ventilation and Airflow

Monitor Temperature and System Alerts

Prevent Overloading and Ensure Proper Use

Schedule Professional Inspections

Preventing overheating in diesel fire pumps is essential for maintaining fire protection reliability. By implementing regular maintenance, optimizing cooling efficiency, and monitoring temperature levels, you can extend the lifespan of your fire pump and ensure uninterrupted fire safety performance.

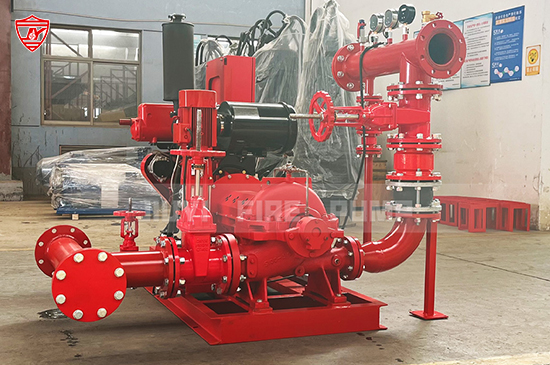

At JIUYI FIRE PUMP, we manufacture high-performance diesel fire pumps designed for durability and safety. Contact us for expert solutions tailored to your fire protection needs!