When it comes to fire protection, downtime is not an option. A leaking fire pump can be alarming, but it doesn’t always mean your entire system needs to shut down. For facility managers, maintenance teams, or anyone responsible for fire safety systems, knowing how to handle a fire pump leak without disrupting operations is crucial.

Before reacting, assess the situation. Is it a minor drip from a fitting or a more serious mechanical seal leak? Minor issues may be managed temporarily while planning a permanent fix.

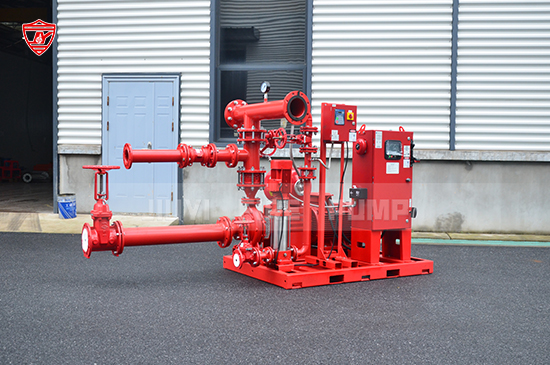

If your system includes a backup (diesel or electric) fire pump, switch operation to the standby unit. This allows the main unit to be inspected or repaired without compromising fire protection.

Most modern fire pump systems are equipped with isolation valves. Close the valves around the leaking section while maintaining pressure and flow through other parts of the system.

Specialized leak sealants, clamps, or epoxy putties can be used as a short-term fix. These products are effective for non-critical, low-pressure leaks and allow time to schedule a proper repair.

A trained professional can assess whether the repair can be safely performed while the system remains operational. They may also advise if a partial shutdown is necessary instead of a full one.

Many leaks result from worn-out gaskets, loose fittings, or neglected seals. Regular inspection and servicing significantly reduce the chance of emergencies that require shutdowns.

Document any incidents and update your emergency procedures. Staff should be trained on how to react quickly and effectively to pump-related issues.