Introduction

Fire safety is a top priority for manufacturing plants due to the inherent risks posed by heavy machinery, electrical systems, and flammable materials. Designing a reliable fire pump system tailored to the plant's unique needs is critical for ensuring effective fire protection.

When designing a fire pump system, it's essential to comply with local and international fire safety standards, such as NFPA 20, which governs the installation of stationary fire pumps. Ensure the system meets insurance and building code requirements to avoid potential issues during inspections.

Each manufacturing plant has unique fire protection requirements. Conduct a thorough risk assessment to determine factors like:

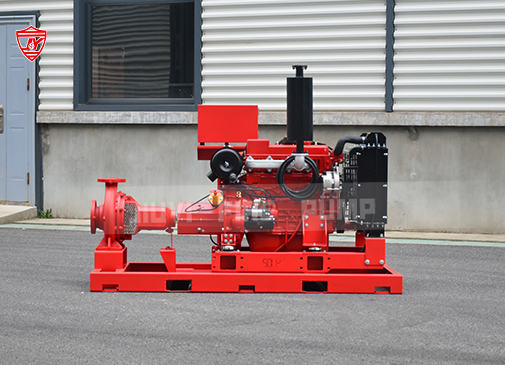

Choose the appropriate fire pump type based on the plant's needs:

Ensure the fire pump can meet the required flow rate and pressure levels. Use hydraulic calculations to ensure water can reach all parts of the facility with adequate pressure, even at peak demand.

The water supply must be sufficient to meet the fire pump's operational needs. Options include:

For critical manufacturing facilities, incorporate redundant systems such as backup pumps and dual power supplies to enhance reliability. Install monitoring systems to track pump performance and detect potential issues in real time.

Regular maintenance is crucial to ensure the fire pump system performs effectively during emergencies. Include features that simplify routine testing and inspections, such as test headers and control panels with diagnostic capabilities.

Conclusion

Designing a fire pump system for a manufacturing plant requires careful planning and compliance with industry standards. By understanding your facility's unique needs and selecting the right components, you can create a robust fire protection solution that safeguards lives and assets.