Fire pumps are a critical component of fire protection systems, ensuring a reliable water supply during emergencies. However, without proper maintenance, a fire pump may fail when needed most. Regular inspections, testing, and servicing are essential to keep your fire pump in optimal working condition and compliant with NFPA 25 standards.

Why Fire Pump Maintenance is Important

A well-maintained fire pump ensures:

✅ Reliable operation in an emergency

✅ Compliance with fire safety regulations

✅ Extended equipment lifespan

✅ Prevention of costly repairs and downtime

Fire Pump Maintenance Checklist

-

Weekly Inspections

- Check for visible leaks, rust, or damage.

- Verify pump pressure gauge readings.

- Ensure diesel or electric power supply is intact.

-

Monthly Testing

- Conduct a churn test to verify pump operation without water flow.

- Check for abnormal vibrations, noises, or overheating.

-

Annual Full-Flow Testing (NFPA 25 Compliance)

- Run the pump at 100%, 150%, and 50% of its rated capacity.

- Measure discharge pressure, suction pressure, and flow rate.

- Inspect pump alignment and coupling connections.

-

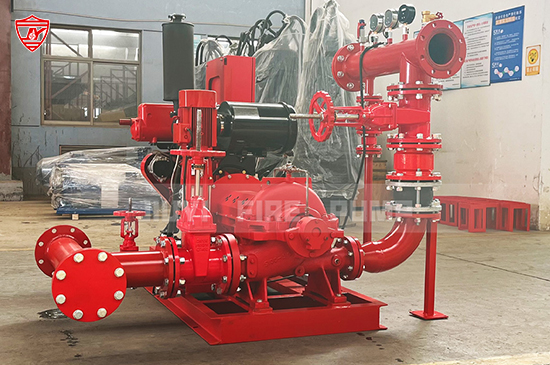

Diesel Engine Fire Pump Maintenance

- Check fuel level, battery charge, and oil pressure.

- Test engine cranking and exhaust system.

-

Electric Fire Pump Maintenance

- Inspect electrical connections and controller settings.

- Test automatic start function and alarm signals.

Common Fire Pump Issues & Troubleshooting

- Low Pressure Output → Check for clogged suction pipes or worn impellers.

- Pump Fails to Start → Inspect power supply, control panel settings, or engine battery.

- Excessive Noise or Vibration → Look for misalignment, loose fittings, or air in the system.